low temperature sterilisation

Highly suitable for high quality electronic components. Sterilization becomes part of the production process.

Low Temprature Sterilizer Canon Medtech Supply

At low concentration levels hydrogen peroxide is a common disinfecting agent sold in pharmacies.

. Easily fits in space-constrained SPDs at less than 2 feet wide. Take the time to review your cleaning rinsing and drying procedures to ensure the best sterilization outcomes. For these reasons the use of EtO is regulated--more strictly in some regions than in others--and many healthcare.

We will see about the Plasma. Viele übersetzte Beispielsätze mit low-temperature sterilisation Deutsch-Englisch Wörterbuch und Suchmaschine für Millionen von Deutsch-Übersetzungen. For all this reason the low-temperature method is necessary.

Low-temperature sterilization is one of the most commonly utilized. Low-temperature Sterilization Market - Global Industry Analysis Size Share Growth Trends and Forecast 2018 - 2026. It has been the most commonly used process for sterilizing temperature- and moisture-sensitive medical devices and supplies in healthcare institutions in the United States.

Highly suitable for thermosensitive plastics. H202 Hydrogen peroxide is used as a sterilant in some of the industries. The basic premise of these Low Temperature units is that steam flows freely at atmospheric pressure.

No deformation or discoloration of plastics. At higher concentration levels it is used as a. Many translated example sentences containing low-temperature sterilisation German-English dictionary and search engine for German translations.

Manufacturers can draw from a broad spectrum of techniques to sterilize and disinfect medical devices and new. Indeed the 1992 edition of Health Building Note 131 said that A department may require in support a. ⑤ Low temperature sterilization The temperature in the sterilization chamber is about 55 which does not damage the equipment and articles and can prolong the service life of valuable medical equipments.

V-PRO s2 Low Temperature Sterilization System. Delivers maximum productivity and maximum flexibility needed to meet SPD and OR demands. This ensures less sterilization time homogeneity of chemical treatment and no residue.

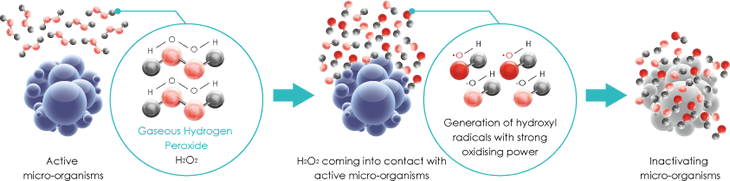

Cleaning rinsing drying testing and packaging of instrumentation can have a direct impact on the success of hydrogen peroxide sterilization. STERILIZATION A new sterilization technique safely treated about 95 of the materials tested in an average of 75 minutes. Ethylene oxide ETO has been widely used as a low-temperature sterilant since the 1950s.

You must first decontaminate instruments and devices before you can run them through a low-temp sterilization cycle. Although EtO can be used safely exposure to this gas is known to be a health hazard and the emissions from certain EtO sterilizers are known to pollute the atmosphere. After decontamination let devices dry completely before you place them in a low-temp sterilizer as moist items cause reprocessing cycles to abort.

Low temperature sterilization uses gaseous or chemical sterilants to sterilize medical devices and instruments at temperatures below 60C 152F1 It is typically used in the reprocessing of temperature- and moisture-sensitive devices which cannot be sterilized using more traditional methods such as steam autoclaves. ⑤ Low temperature sterilization The temperature in the sterilization chamber is about 55C which will not damage the equipment and items can prolong the service life of valuable medical equipment and have a good sterilization effect. 4 Tips for Getting Low-Temperature Sterilization Right 1.

However of these the most common cycle is the Low Temperature Cycle which can be programmed to operate at temperatures between 158212F 70100C with no chamber pressure. Short circulation times of instruments. Ethylene oxide has been used as a low-temperature sterilization technology since the 1950s.

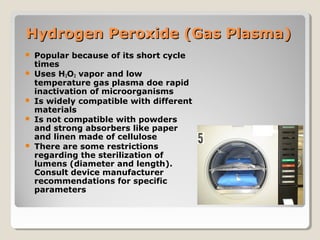

For this reason the sterilization chamber was made of aluminum with a good thermal conductivity that allows to maintain the constant temperature. Compatibility of Medical Devices and Materials with Low-Temperature Hydrogen Peroxide Gas Plasma. Plasma Before getting into the working advantages and disadvantages.

Preparation Packaging for VHP Low-Temp Sterilization The sterilization process is complex. ⑥Safe and stable The system has a strict automatic detection function which monitors the sterilization process in real time. Therefore we must find a low temperature sterilization method that is more delicate on the life of the equipment but still effective enough to fully sterilize all germs on said equipment.

LTGP sterilization is now performed approximately 55 million times a year in healthcare settings worldwide. Process up to 4 lb 18 kg of non-lumened and lumened devices in only 19 minutes in the exclusive Fast Cycle. The available data demonstrate that low-temperature sterilization technologies are able to provide a 6-log 10 reduction of microbes when inoculated onto carriers in the absence of salt and serum.

Enter hydrogen peroxide also known as H2O2. There are different technologies on the market for use in low-temperature LT sterilization processes for reprocessing medical devices in industrial settings in central sterile supply departments. 4 In this process an aqueous hydrogen peroxide solution boils in a heated vaporizer and then flows as a vapor into a sterilization chamber containing a load of instruments at low pressure and low temperature.

It is one of the most common Disinfecting Agents available. However one difference between departments in the UK when compared to other countries is the lack of use of low temperature sterilisation. Exposure to the hydrogen peroxide vapor.

Low operating temperature of 45-55C. Gentle treatment of sterilized products. Twenty years ago most UK sterile service departments SSDs used a low temperature steriliser.

Low-temperature hydrogen peroxide is very sensitive to the temperature difference in the sterilization chamber. Commonly used test organisms include vegetative bacteria mycobacteria and spores of Bacillus species. Two types of ETO sterilizers are available mixed gas and 100 ETO.

Sterilization is a process that kills or eliminates harmful agents such as viruses bacteria and fungi from equipment food medication and biological media.

Low Temperature Sterilising Medon

Hydrogen Peroxide Plasma Sterilizer Suppliers Manufacturers Good Price Cfull

Low Temperature Plasma Sterilizer With Hydrogen Peroxide Youtube

Low Temperature Sterilization System Receives 510 K Clearance Medgadget

Low Temperature Sterilization Technology Ppt Download

Chapter 16 Low Temperature Sterilization

Low Temperature Sterilization Technology Ppt Download

Formomat Pl Mmm Medcenter Einrichtungen Gmbh

Low Temperature Sterilising Medon

Iq Oq Pq Validation Of Hydrogen Peroxide Low Temperature Plasma Sterilizer Tsquality Ch

H2o2 Low Temp Plasma Sterilizer Lianyungang Youyuan International Trading

Pdf Low Temperature Sterilization Processes Pros And Cons As Reported Over Two Decades In Central Service

Low Temprature Sterilizer Es 700 Canon Medtech Supply

Comparative Analysis Of Low Temperature Sterilization Methods Download Table

V Pro 60 Low Temperature Sterilization System Steris

V Pro 1 Low Temperature Sterilization System Steris

Comments

Post a Comment